You will not be allowed to compare more than 4 products at a time

View compare

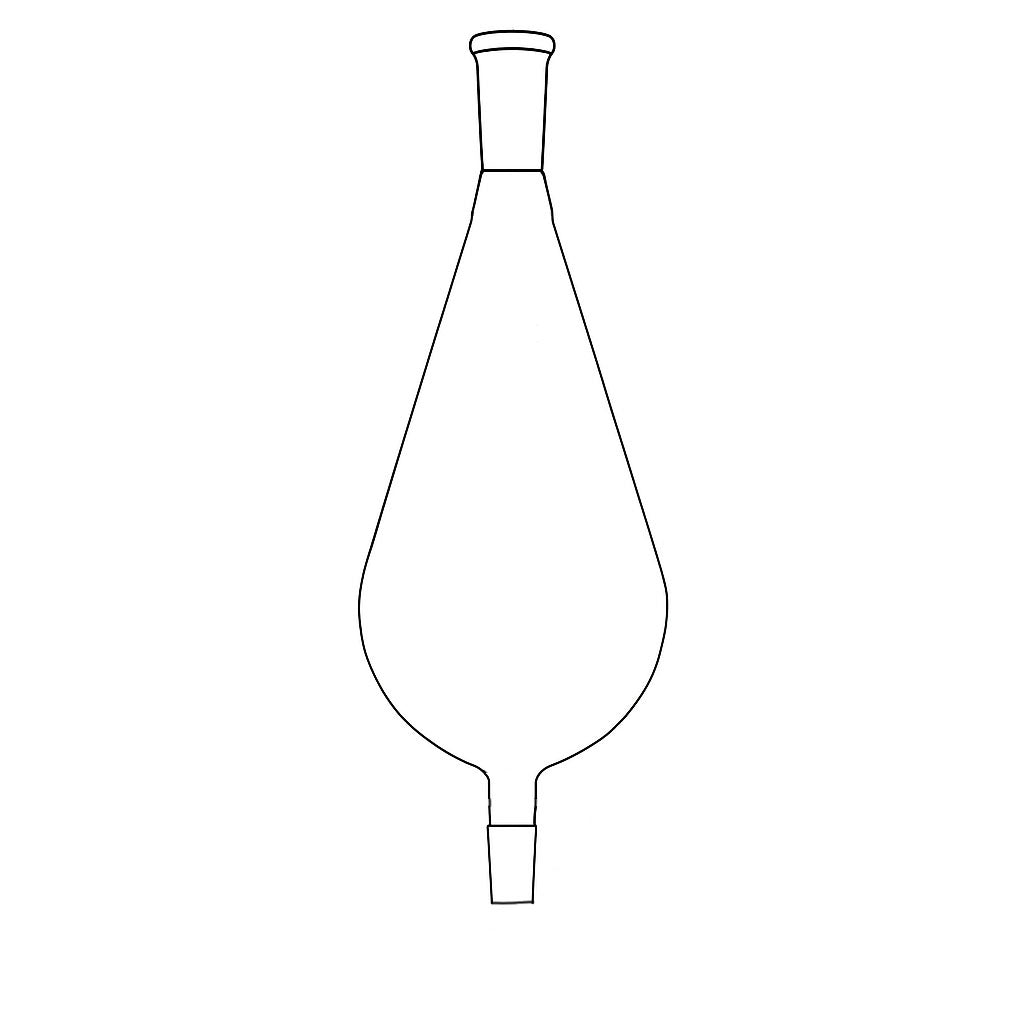

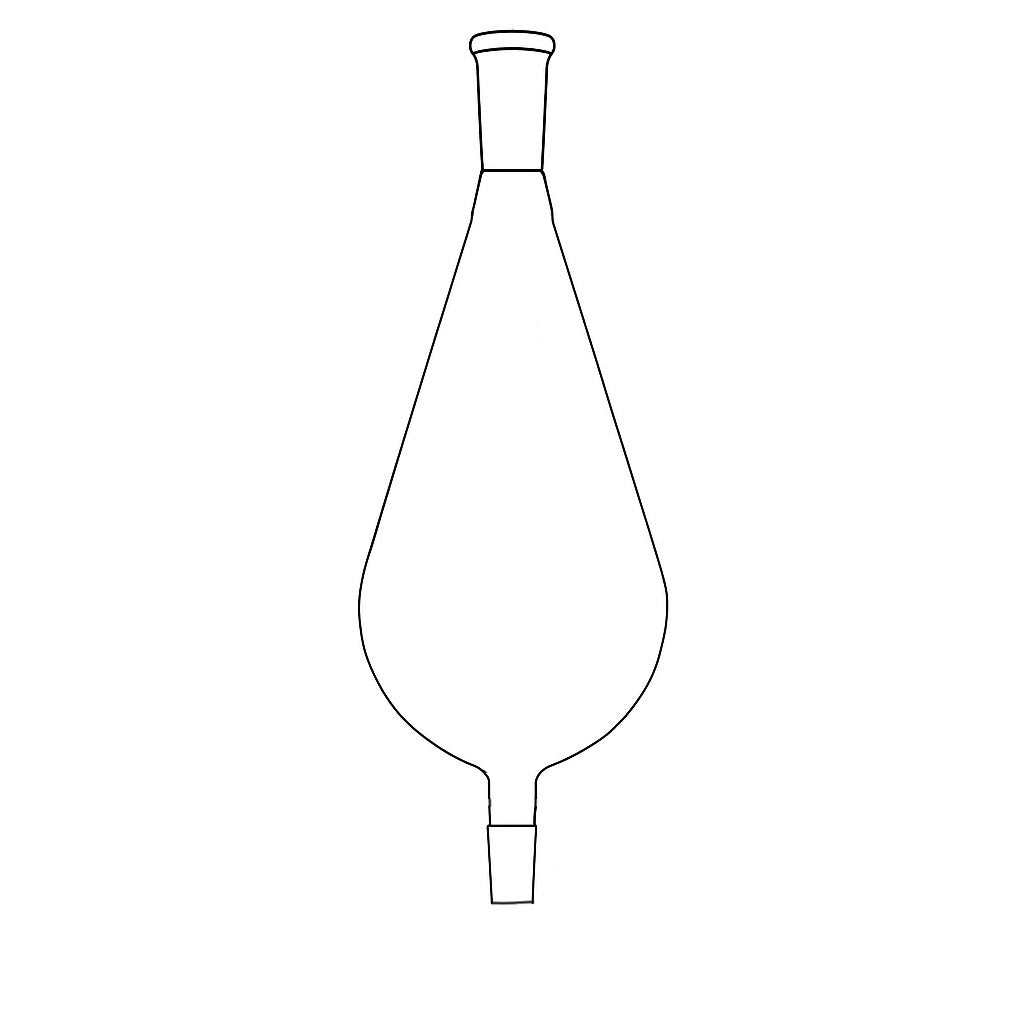

KD (Kuderna–Danish) flask is a laboratory glassware component commonly used for solvent concentration workflows, especially in analytical methods where controlled evaporation and consistent recovery are important. Often paired with a KD concentrator system (including a Snyder column and concentrator tube), the KD flask supports routine sample preparation for environmental testing, chemical analysis, and quality control labs. Its purpose is straightforward: provide a stable, heat-tolerant vessel that integrates cleanly into concentration setups and helps users process samples efficiently without unnecessary handling.

Stone Glass manufactures KD flasks from borosilicate glass designed for laboratory use. Borosilicate is valued for its thermal performance and durability in common heating and evaporation procedures. Whether your process uses a water bath, gentle reflux, or controlled evaporation, a properly made KD flask helps maintain predictable function across repeated runs. The shape and connection points of the flask are intended to promote smooth operation with compatible KD glassware components while keeping the setup easy to assemble, disassemble, and clean.

Designed for common KD concentration workflows

KD flasks are typically selected when labs need to concentrate extracts after preparation steps such as liquid-liquid extraction or other cleanup procedures. In many workflows, the flask is connected to other KD components so that vapor can be managed and solvent can be reduced in a controlled way. The result is a more manageable final volume that can be transferred for further analysis (for example, instrument testing or additional preparation). A good KD flask supports this process by providing a consistent fit, stable base geometry, and reliable glass-to-glass connections.

Because KD systems are often used repeatedly, consistency matters. A flask that seats properly and aligns well with connected components helps reduce set-up time and lowers the chance of leaks or awkward fit-up. In practice, this can save time during busy sample-prep days and improve overall lab workflow.

Quality-focused construction

A KD flask should be more than “close enough.” Connection accuracy, smooth transitions, and clean internal surfaces all matter for real lab use. We focus on glasswork that supports practical performance: joints that assemble smoothly, clean contours that reduce residue traps, and careful finishing so the glass is comfortable to handle and easier to maintain. If your KD setup includes standardized joint sizes, we can build to those specifications so your flask integrates into your existing system.

If your lab has a preferred geometry, capacity, or joint configuration, we can support custom builds and repeat orders. Many labs and organizations prefer to standardize their sample prep tools across multiple teams or locations. When you’re ready for repeat builds, consistent fabrication helps ensure that replacement pieces match your established setup.

Options and customization

KD flasks may vary by volume, joint size, and configuration depending on the application and the concentrator components being used. If you need a specific capacity, a particular joint size, or compatibility with an existing Snyder column or concentrator tube, provide your specifications (or a photo/drawing of the current piece) and we’ll help you match it. We can also support private labeling for organizations that need their own identification on lab glassware for inventory control, standard operating procedures, or resale programs.

Typical applications

KD concentration systems are commonly associated with:

Environmental laboratory sample preparation

Analytical chemistry workflows

Quality control (QC) and process checks

Method-driven concentration steps where consistent recovery is important

Top Joint is a 24/40 outer while the lower joint is a 19/22 inner. Available with and without hooks on the lower 19/22 inner joint.

Manufactured with pride in Vineland, New Jersey, USA

All Glassware is individually inspected against manufacturing drawings, and Certificates of Conformity are available upon request to meet QA/QC documentation requirements.